Dye Sublimated Mugs

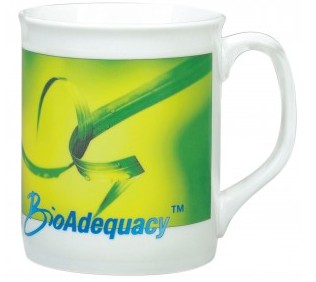

Do you want your mug to be printed in a gorgeous full colour print with all your logos and cool funky graphics? Alternatively were you not content with having your graphic simply printed on 1 side of the mug? Well if you answered to YES to either or both these questions then you may be interested in Dye Sublimated Mugs.

What is a Dye Sublimated Mug?

A dye sublimation is a process of branding on mugs which is a little bit different and a little bit more special than ordinary. A dye sublimation allows for essentially photo quality prints onto a mug. It is a branding process which is significantly different to regular mug branding methods such as kiln firing. To dye sublimate a mug the basic process is as follows:

1) Your Image is printed onto a special film which is printed with your graphic

2) This film is hand applied to the mug. (the area around where the handle cannot be printed or covered)

3) The film is removed and a heating process is applied which evaporates the dye colours and leaves the image behind which solidifies with the cerramic or porcelain.

Advantages of Using Dye Sublimation on Mugs

Dye sublimation looks fantastic and allows for a wrap around print. The print result is also quite durable too to daily knocks. Couple with the fact that they also resist washing machine temperatures and you have a mug branded with your details that is quite durable. Dye sublimation can be applied to both ceramic promotional mugs and also to porcelain promotional mugs.

Disadvantages of Using Dye Sublimation on Mugs

The dye sublimation print process costs more than regular kiln fired mugs. There are several reasons behind this including:

- Longer production time

- Increase in ink costs

![]()

- Production process more expensive than kiln firing

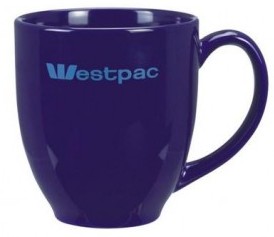

This print process is also not available on mugs that do not have a continuos surface. For example regular can shaped kitchen mugs will be perfect for this print process but if you were to opt for say a mugs that have a bit of curve or perhaps were a bit rounded it would not be possible to print on them using the dye sublimation process. For example the image below shows a white mug with essentially straight sides. This would be perfect for dye sublimation. The other blue mug though is not suitable as the sides are round and tapers down into the base which makes hand application of the dye sublimation transfer print impossible.